High-frequency induction heating furnace with automatic feeding equipment

Automatic feeding devices can be planned and designed according to the on-site space and the size of the heating billets. For shorter billets, a rotary disc vibration feeder paired with servo motors or variable frequency motors driving roller conveyors is suitable for feeding. For longer billets, a stepwise feeding mechanism combined with cylinder pushing is appropriate to feed the billets into the heating coils.

The human-machine interface enables programmable control of the system.

The system utilizes a Japanese Mitsubishi PLC in conjunction with a Pro-face human-machine interface monitoring system. Its features include customizable billet size specifications and combination modes (the quantity of combinations is adjustable based on customer requirements), press machine trial or abnormal pause discharge insulation modes, billet low temperature or over-temperature selection settings, etc. The interface is designed for easy operation in Chinese.

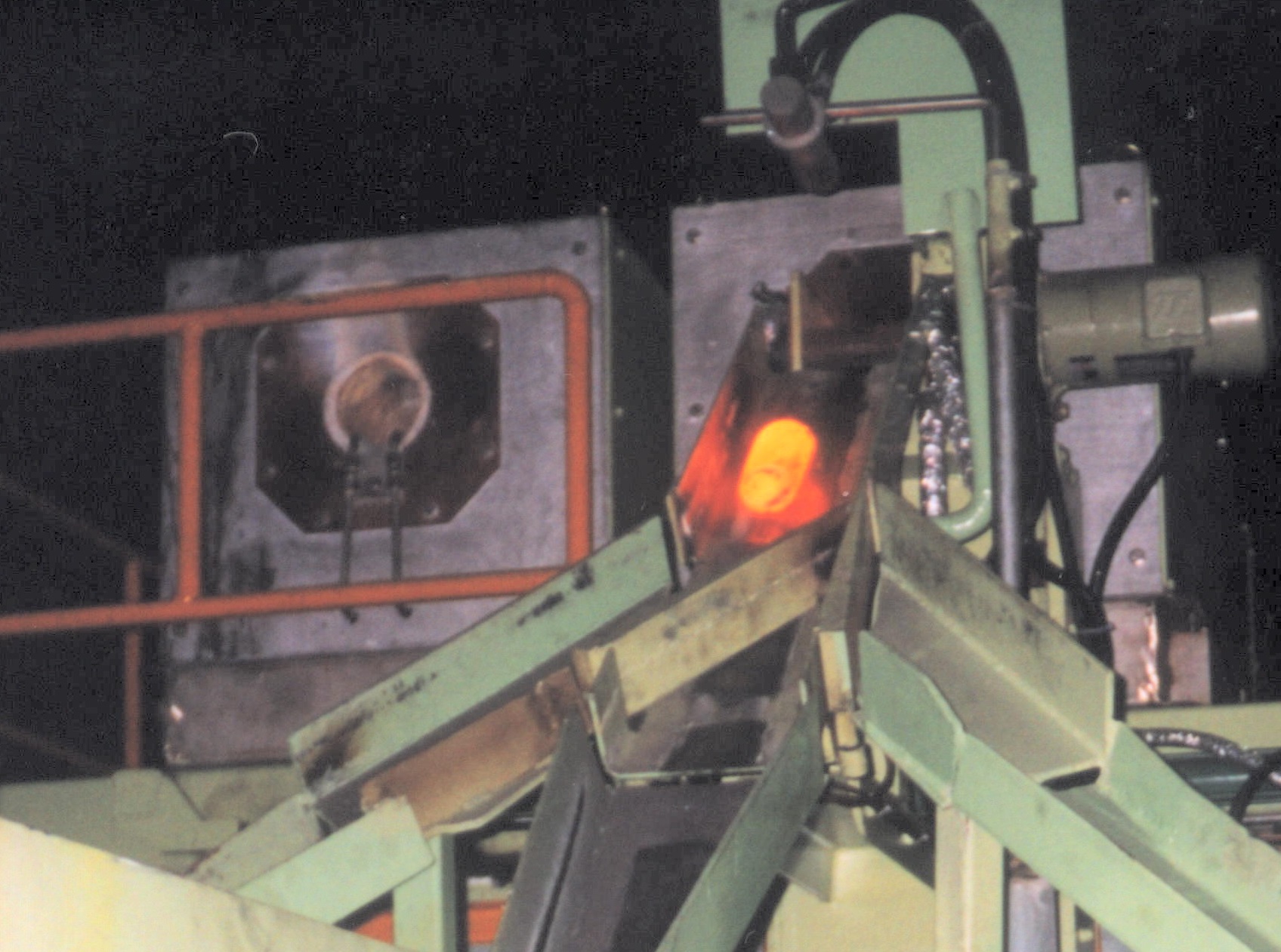

A high-precision infrared thermometer automatically detects overheating or insufficient temperature of billets for convenient rejection. It adjusts the power supply to reduce power consumption during overheating and compensates to harmonize and optimize power supply during low temperatures, ensuring both heating quality and maximum energy savings.

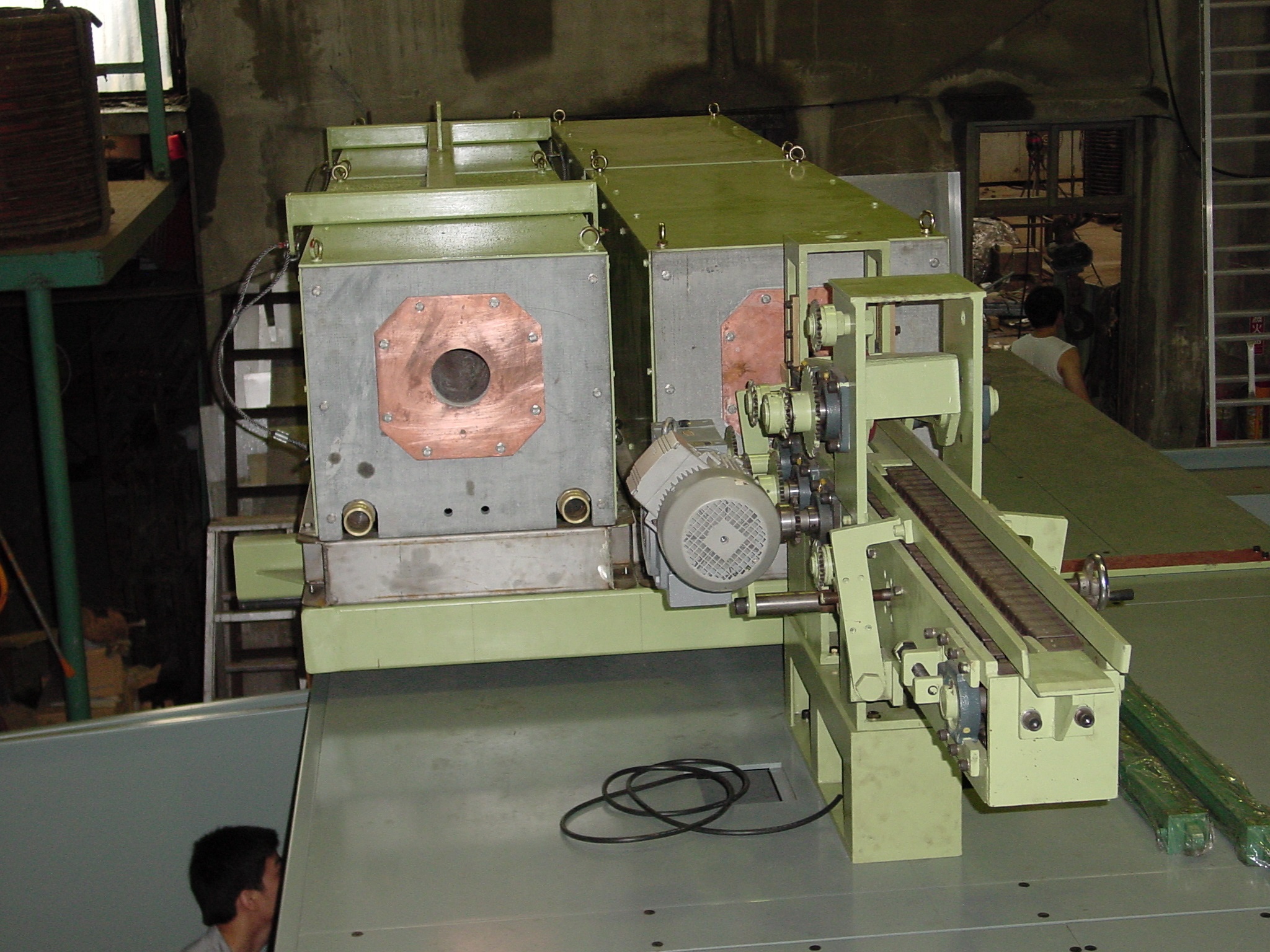

When the steel billet size changes, the furnace body switches rapidly, automatically introducing copper bars. The furnace cooling system adopts quick-connect joints for connecting cooling water pipes, reducing the switching process time to approximately two minutes, thus saving time and effort.